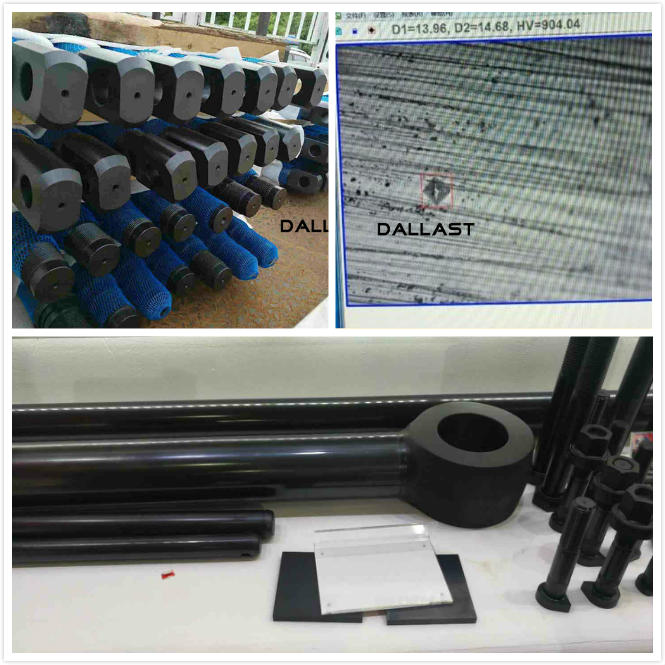

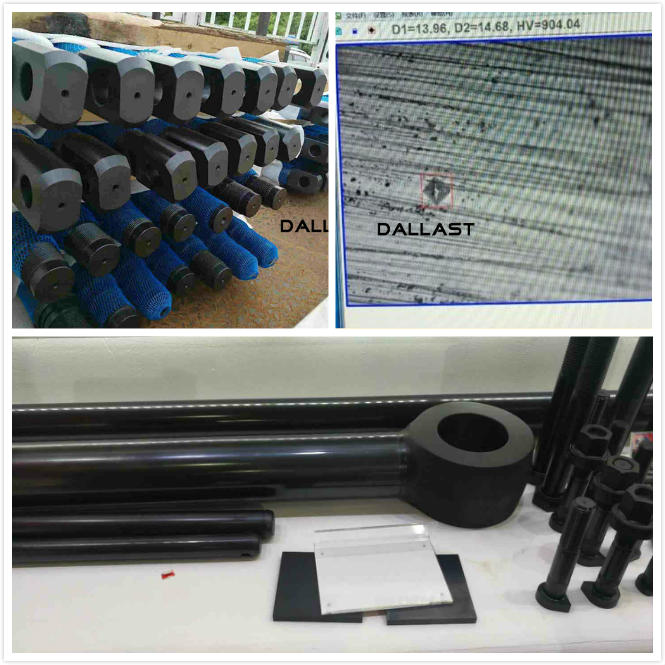

45# 42CrMo Piston Hollow Rods Hard Chrome Plated Steel Bar NSS 800

Hours

Material :45# 42CrMo

Color :Black

NSS:Endure 300;500;800hours

Type:Hollow/Solid Rod

Application Environment:At sea or in harsh environments Surface

hardness:>HV860

SURFACE ROUGHNESS:Ra≤0.2 micron and Rt≤2 micro

TOLERANCES ON DIA:ISO f10 on the diameter

LENGTH:MAX 5 meter

Testing Standing une-en iso9227:2017

· Sal solution: 50 (+/- 5) g/l of NaCl. Water is demineralized and

salt purity is 99.5%.

· Environmental temperature: 35 °C.

· pH of salt solution is 6.8.

· Volumen of salt solution is 38.4 ml/day.

· Density of salt solution is 1,030 g/cm3.

· Spraying is 1.5 (+/- 0.5) ml/h.

Test Result :NSS can endure 300 hours ;500 hours; 800 hours

In the whole crafts process, there are 2 times remove hardening forces: the first remove hardening force in the

heat treatment process, hardening force remove is about 80%; the second remove hardening force in the surface treatment

process, hardening force remove is about 90%-95%. Therefore, the piston rod is not easily deformed during use or

transportation.

CHEMICAL COMPOSITION

| Material | C% | Mn% | Si% | S% | P% | V% | Cr% |

| Ck45 | 0.42-0.50 | 0.50-0.80 | 0.04 | 0.035 | 0.035 | | |

| ST52 | 0.22 | 1.6 | 0.55 | 0.035 | 0.04 | | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.10-0.50 | 0.035 | 0.035 | 0.10-0.20 | |

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | | 0.90-1.20 |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | | | | 0.80-1.10 |

MECHANCIAL PROPERTIES

| Material | T.S N/MM2 | Y.S N/MM2 | E%(MIN) | CHARPY | CONDITION |

| CK45 | 610 | 355 | 15 | >41J | NORMALIZE |

| CK45 | 800 | 630 | 20 | >41J | Q + T |

| ST52 | 500 | 355 | 22 | | NORMALIZE |

| 20MnV6 | 750 | 590 | 12 | >40J | NORMALIZE |

| 42CrMo4 | 980 | 850 | 14 | >47J | Q + T |

| 40Cr | 1000 | 800 | 10 | | Q + T

|